In outdoor advertising, sports venues, and public installations, modular LED display panels face one of their greatest challenges — extreme heat. High temperatures can affect brightness, color stability, and even the lifespan of LED modules. Therefore, understanding how these systems maintain stable performance in demanding environments is crucial for professional buyers and engineers.

The Impact of Heat on Modular LED Displays

Heat significantly influences electronic components. When the temperature rises, LED chips generate more resistance, reducing luminous efficiency and accelerating light decay. De plus, excessive heat may damage solder joints or driver ICs, leading to flicker or partial failure. However, modern modular LED display panels are engineered with advanced thermal control systems to prevent these issues and sustain high performance.

Advanced Cooling and Heat Dissipation Solutions

To operate normally in high-temperature environments, manufacturers integrate several cooling strategies. Many panels feature aluminum alloy backplates that conduct heat efficiently, while ventilation holes et heat pipes help maintain even temperature distribution. Some high-end modular LED displays even use intelligent temperature control chips, which adjust brightness automatically based on real-time thermal readings.

En outre, active cooling systems, such as low-noise fans or convection-based designs, improve airflow across modules. These technologies work together to ensure that every LED pixel performs consistently, even under direct sunlight.

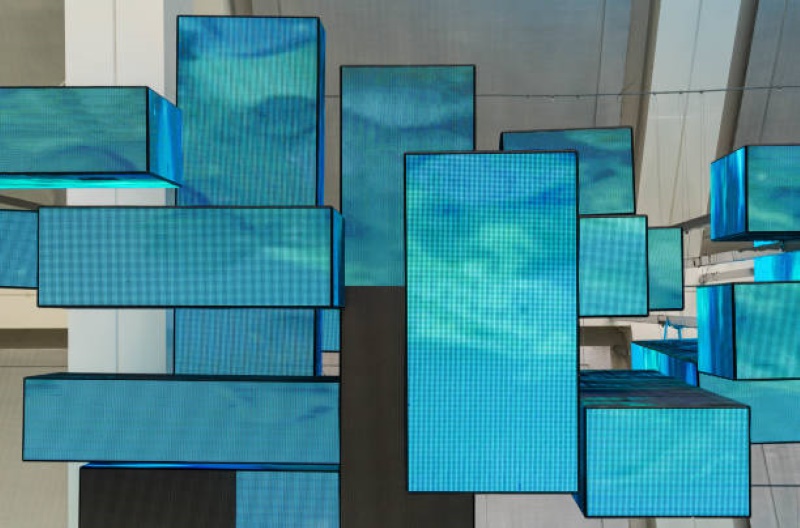

LED billboards in the basement

Material and Component Optimization

In addition to heat dissipation, material selection plays a decisive role. Le PCB substrate in modular LED display panels uses high thermal conductivity materials to enhance efficiency. Encapsulation resins et UV-resistant coatings protect against thermal deformation and long-term exposure to sunlight.

En plus, power supplies are designed to deliver stable voltage across a wide temperature range. This ensures consistent brightness and reduces the risk of performance fluctuations during hot summer days.

Design Adaptations for Outdoor Applications

Outdoor modular LED displays must handle both temperature and humidity changes. Therefore, many models achieve IP65 or higher waterproof ratings while maintaining excellent heat exchange performance. Le modular structure also simplifies maintenance — faulty units can be replaced quickly without disrupting the entire system.

These design advantages make modular LED display panels suitable for stadiums, centres de transport, and commercial billboards in regions with intense sunlight or hot climates.

Reliability Testing and Performance Validation

Before reaching the market, each display undergoes rigorous thermal and aging tests. These include 72-hour high-temperature aging, thermal shock simulations, et continuous operation under elevated humidity. Through these tests, manufacturers verify that the display’s luminous intensity, uniformity, and electronic stability remain within safe limits.

Such strict validation ensures that LIKELED’s modular LED display panels maintain outstanding performance, even when surface temperatures exceed 60°C.

Conclusion: Intelligent Design for Extreme Conditions

Ultimately, modular LED display panels continue to deliver reliable visuals in high-temperature outdoor environments because of their advanced materials, intelligent heat management, and modular construction. As outdoor digital signage expands globally, these technologies ensure that displays remain bright, stable, and energy-efficient — no matter how hot the environment becomes.